Timeless Gold Creations

CRAFTED ELEGANCE

Explore our exclusive collection of fine gold jewelry, crafted to celebrate every moment with timeless beauty.

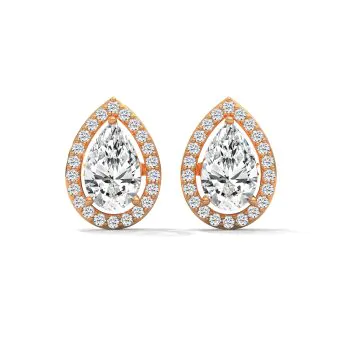

Shimmer with Diamonds

DAZZLING BRILLIANCE

Discover our exquisite diamond jewelry, designed to add unparalleled brilliance to your special occasions.

The Art of Gemstones

VIBRANT RADIANCE

Experience the allure of natural gemstones, from faceted brilliance to the raw beauty of rough stones.

Welcome to Jaitam Jewels

Discover a world where tradition meets modern sophistication. At Jaitam Jewels, we create stunning jewelry pieces that celebrate life’s most cherished moments. From intricate designs that honor heritage to contemporary styles that shine with individuality, we have something for every taste and occasion.

How it Works

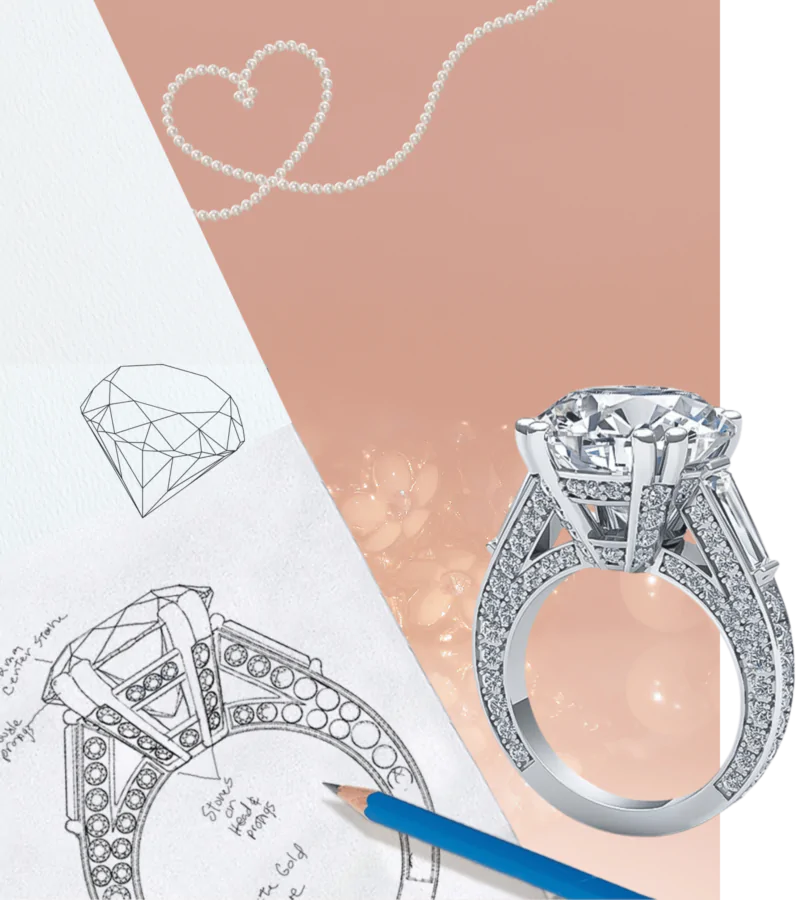

CAD

We push creative boundaries in jewelry design. CAD enables precise 2D or 3D models, providing a full view from all angles and allowing easy adjustments to fit your vision.

Sample

Once the CAD is approved, we create a prototype for you to physically examine. This helps you visualize the final product and suggest any changes, which can be easily made.

Production

After the sample is approved, we produce the designs in bulk and ship them quickly. The high-resolution prototype ensures smooth casting, molding, and reproduction processes.

We push creative boundaries in jewelry design. CAD enables precise 2D or 3D models, providing a full view from all angles and allowing easy adjustments to fit your vision.

Once the CAD is approved, we create a prototype for you to physically examine. This helps you visualize the final product and suggest any changes, which can be easily made.

After the sample is approved, we produce the designs in bulk and ship them quickly. The high-resolution prototype ensures smooth casting, molding, and reproduction processes.

We are the manufacturer of

How Are We Different

- A Personalised Experience

We understand all your ideas as it’s our own brain child.

- Recycled Metal

All our metals are recycled wherever possible. Its our contribution towards keeping environment safe.

- From Ideas to Shipment

Whatever design you can think of we ensure to take all the knowledge transfer and ship you the final products at your door step.

- Lower MOQ

We understand the needs to test designs in market and hence our minimums are bare minimum.

- Sample First

It’s very important to see the product first before selling it to users, hence for all the designs you’ll be getting samples first.

- Skilled Labours

Our labours consist of professional gold and silver smiths only having 5+ years of experience.

Who do we work for?

Jewellery Store Owners

Jewellery Store Owners

We believe in uplifting everyone. If you are someone who is looking for jewellery manufacturers for your store, we assure you to bring the best to you.

Jewellery Designers

Jewellery Designers

Designer jewellery is very delicate and requires a lot of precision while manufacturing. Most designers struggle to find the perfect manufacturers who understand and create their designs with finesse. Designers create the magic and we manufacture the magic.

Jewellery Brands

Jewellery Brands

We take bulk orders of the renowned brands and also support you if you are someone who is starting a brand of their own. We know all about the jewellery market, the jewellery trends, and your potential customers! We will help you make the most beautiful and unique jewellery for your brand.

Individuals

Individuals

If you are someone who designs your jewellery and want your designs in real form, we are there for you. You do not need to have a big brand name to support your designs. You just need the right idea and design and we will make it for you.

Affiliation & Certification

Production Process

01

CAD

With the help of Computer-Aided Design,

we show you what your final Jewelry will look like.

This helps you to edit all the details before moving to production.

3D PRINTING

Once the CAD is approved, the jewelry design is printed as a next step

and all the design nitty-gritty is detailed checked.

02

03

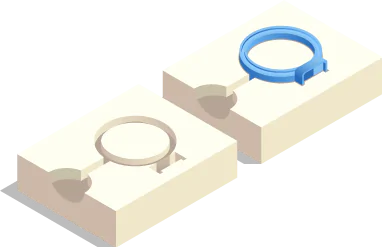

MOLDING

The 3D printed jewelry design is poured with silicone to make

the mold which helps to make bulk jewelry at a rapid speed.

CASTING

At this stage, melted metal platinum/gold/silver/brass is poured

into to resin from mold and kept to cool off until it takes the design shape.

04

05

STONE SETTING

With the help of Computer-Aided Design,

we show you what your final Jewelry will look like.

This helps you to edit all the details before moving to production.

FINISHIING

All the additional metal from casting is cleaned and finished using

high-quality equipment tools to give scratchless quality.

06

07

PLANTING

Plating starts with an intensive cleaning. This eliminates any soil, oil, rust,

or other buildup and the put into a plating bath.

ENGRAVING

The final and last step is to put your brand name

engraved on the designs with your font & size.

08

CAD

With the help of Computer-Aided Design, we show you what your final Jewelry will look like. This helps you to edit all the details before moving to production.

PRINTING

Once the CAD is approved, the jewelry design is printed as a next step and all the design nitty-gritty is detailed checked.

MOLDING

The 3D printed jewelry design is poured with silicone to make the mold which helps to make bulk jewelry at a rapid speed.

CASTING

At this stage, melted metal platinum/gold/silver/brass is poured into to resin from mold and kept to cool off until it takes the design shape.

STONE SETTING

With the help of Computer-Aided Design, we show you what your final Jewelry will look like. This helps you to edit all the details before moving to production.

FINISHIING

All the additional metal from casting is cleaned and finished using high-quality equipment tools to give scratchless quality.

PLANTING

Plating starts with an intensive cleaning. This eliminates any soil, oil, rust, or other buildup and the put into a plating bath.

ENGRAVING

The final and last step is to put your brand name engraved on the designs with your font & size.

With the help of Computer-Aided Design, we show you what your final Jewelry will look like. This helps you to edit all the details before moving to production.

Once the CAD is approved, the jewelry design is printed as a next step and all the design nitty-gritty is detailed checked.

The 3D printed jewelry design is poured with silicone to make the mold which helps to make bulk jewelry at a rapid speed.

At this stage, melted metal platinum/gold/silver/brass is poured into to resin from mold and kept to cool off until it takes the design shape.

Our Blog

FAQ

Absolutely. We are happy to sign an NDA before proceeding as well.

We ship all over the world

We work with all types of metals, precious and semi-precious stones – Gold, Silver, Brass, Diamonds, Moissanite, and much more

We take 60% advance, 20% on physical sample approval, and 20% on production completion.

We take a minimum of 30 Pieces per design for Artificial Jewelry & there is no MOQ for fine jewellery.